Allen Organ's commitment to produce digital church organs and related musical instruments of the highest quality has enabled us to maintain leadership in the industry for many decades. An accomplishment such as this can only be attained when all involved in manufacturing our end product take a personal interest in seeing that their contribution meets the highest level of quality. It is this work ethic that pervades at Allen Organ!

Allen Organ Company is looking for you to join our team! We are a manufacturing company located in Macungie, PA (Lehigh Valley). We build Organs for churches and other customers, using digital technology. Our manufacturing processes include our Wood & Cabinet Shop, Sanding and Finishing, Cabinet Fitting, Final Assembly & Test and Shipping, in addition to having a Metal Shop.

We have several openings in our manufacturing plant. Attendance and reliability are important. We run one shift 7:30am to 4:00pm with a 30-minute unpaid lunch and 2 paid 10-minute breaks. We work overtime if needed but notify employees in advance.

Our company has been in business for over 80 years and offer a competitive compensation and benefit package. We are willing to train and can provide opportunities for cross training within most departments.

If you are interested in learning more about our job opportunities, please send your resume to careers@allen-organ.com.

SENIOR EMBEDDED HARDWARE/SOFTWARE ENGINEER

Allen Organ Company is seeking a Sr. Embedded Hardware/Software Engineer. The Sr. Embedded Hardware/Software Engineer is a key team member in the Research and Development Department. In this role, you will work with the internal team to design and develop electronic assemblies from the initial schematic through production in coordination with other departments. This position will report to the Chief Engineer here at our location in Macungie, PA. The hours are based on production which are 7am to 4pm Monday through Friday. This is an onsite position.

Interested candidates should submit resume to careers@allen-organ.com for consideration.

Essential Duties and Responsibilities:

Qualifications:

Requirements:

Benefits:

Allen Integrated Assemblies (AIA), a division of Allen Organ Company, is looking for you to join our team! We are located in Macungie, PA (Lehigh Valley) and are a full service electronic and electro-mechanical contract manufacturer specializing in the manufacture and testing of electronic assemblies. Our manufacturing processes include printed circuit board (PCB) assembly, mechaical assembly, testing, inspection, and quality control. We are ISO 9001 Certified.

We have several openings in our AIA division. Attendance and reliability are important. We run one shift 7:30am to 4:00pm with a 30-minute unpaid lunch and 2 paid 10-minute breaks. We work overtime if needed but notify employees in advance.

Our company has been in business for over 80 years and offer a competitive compensation and benefit package. We are willing to train and can provide opportunities for cross training within most departments.

If you are interested in learning more about our job opportunities, please send your resume to careers@allen-organ.com.

BUYER

Allen Integrated Assemblies (AIA) is seeking a Buyer to join our team. In this role, the Buyer is responsible for sourcing, negotiating, and purchasing electronic components and materials required for our manufacturing operations. The role ensures timely procurement, cost efficiency, and quality compliance while fostering and maintaining positive supplier relationships and supporting production schedules. This position is onsite at our location in Macungie, PA. The hours are based on production which are 7:30am to 4:00pm Monday through Friday.

Interested candidates should submit resume to careers@allen-organ.com for consideration.

Essential Duties and Responsibilities:

Qualifications:

Requirements:

Benefits:

STOCKROOM SUPERVISOR

Allen Integrated Assemblies (AIA) is seeking a Stockroom Supervisor to join our team. In this role, the Stockroom Supervisor oversees the daily operations of the stockroom in the AIA division. In addition, the person in this role will also be responsible for ensuring accurate inventory management, timely receiving and shipping of product, and accurate component part assembly. This position will sit in the manufacturing environment at Allen Integrated Assemblies located in Macungie, PA. The hours are based on production which are 7:30am to 4:00pm Monday through Friday. This is an onsite position.

Interested candidates should submit resume to careers@allen-organ.com for consideration.

Essential Duties and Responsibilities:

Qualifications:

Requirements:

Benefits:

GROUP LEADER OF PC BOARDS

Allen Integrated Assemblies (AIA) is seeking a Group Leader of PC Boards to join our team. In this role, the Group Leader will perform the job duties of the PC Board Assembler but also assist with ensuring the production process is on track to meet required deadlines and quality standards. The hours are based on production which are 7:30am to 4:00pm Monday through Friday. This is an onsite position.

Interested candidates should submit resume to careers@allen-organ.com for consideration.

Essential Duties and Responsibilities:

Qualifications:

Requirements:

Benefits:

ALLEN ORGAN COMPANY, LLC

Allen Organ Company is an Equal Employment Opportunity Employer.

Lehigh Valley Economic Development Corporation - www.lehighvalley.org - demographics of the region, business and cultural opportunities available and information on recent news and events.

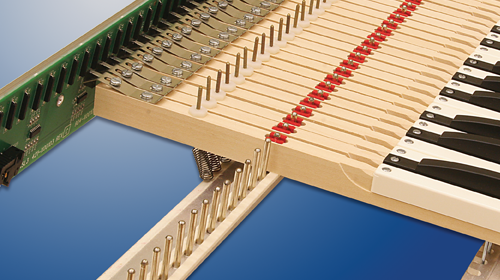

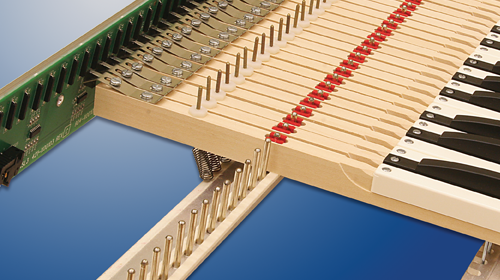

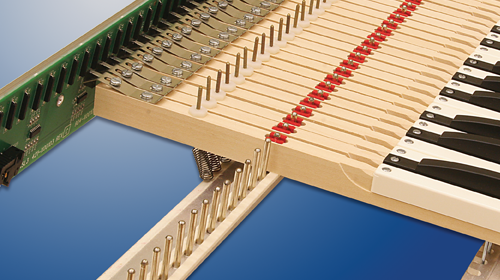

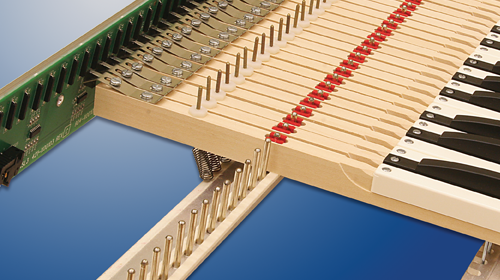

PREMIUM KEYBOARDS

The Allen keyboard utilizes sealed contacts and wood keysticks to provide the ultimate in touch and control. The level of quality and adjustability of Allen keyboards makes them the envy of the industry and the choice of discerning musicians.

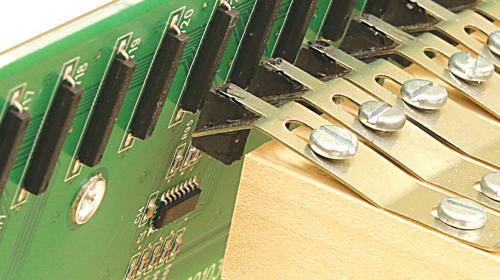

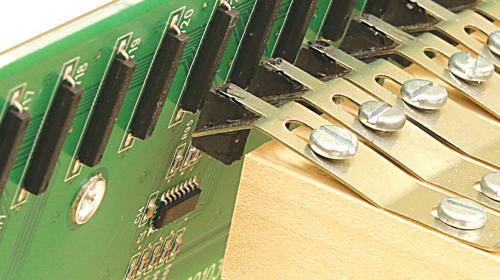

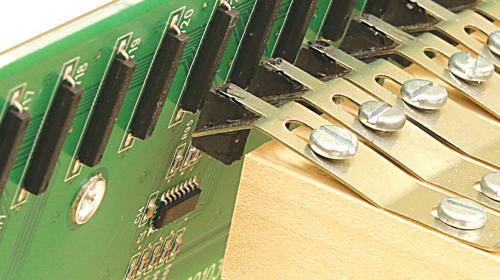

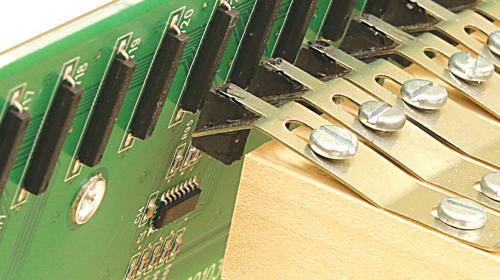

KEY CONTACT

The key contact, while unseen, is an important part of any church organ. If one fails during a performance, the entire musical program can be compromised. Allen introduced a maintenance-free system in which a sealed reed switch is engaged by magnet. Neither dust nor the environment will compromise your music program with an Allen Organ.

PREMIUM KEYBOARDS

The Allen keyboard utilizes sealed contacts and wood keysticks to provide the ultimate in touch and control. The level of quality and adjustability of Allen keyboards makes them the envy of the industry and the choice of discerning musicians.

KEY CONTACT

The key contact, while unseen, is an important part of any church organ. If one fails during a performance, the entire musical program can be compromised. Allen introduced a maintenance-free system in which a sealed reed switch is engaged by magnet. Neither dust nor the environment will compromise your music program with an Allen Organ.

TO-5X SPECIFICATIONS

Featuring Four Stop List Scaling/Voicing Capability

PEDAL

32 Contra Diaphone

32 Contra Tibia S

32 Contra Violone

16 Double English Horn

16 Bombarde

16 Ophicleide

16 Diaphone

16 Diaphonic Horn

16 Tibia Clausa S

16 Tibia Clausa M

16 Clarinet

16 Bass String (2 rks)

16 Oboe Horn

16 Violone

16 Bourdon

16 Dulciana (2 rks)

8 English Horn

8 Tuba Mirabilis

8 Tuba Horn

8 Diaphonic Diapason

8 Open Diapason

8 Horn Diapason

8 Tibia Clausa

8 Tibia Clausa

8 Tibia Clausa

8 Tibia Clausa PIZZ

8 Clarinet

8 Major Strings (4 rks)

8 Minor Strings (6 rks)

8 French Horn

8 Oboe Horn

8 Concert Flute

16 Piano

8 Piano

Bass Drum

Tympani

Crash Cymbal

Tap Cymbal

Brush Cymbal

Finger Cymbals

Triangle

Accomp to Pedal

Great to Pedal

Great Octave Pedal

Solo on Pedal

MIDI on Pedal

Accomp Traps to Pedal

ACCOMPANIMENT

8 English Horn

8 Tuba Mirabilis

8 Solo Trumpet

8 Chorus Trumpet

8 Tuba Horn

8 Diaphonic Diapason

8 Open Diapason

8 Horn Diapason

8 Tibia Clausa S

8 Tibia Clausa M

8 Clarinet

8 Solo String (2 rks)

8 Gamba (2 rks)

8 Cello (2 rks)

8 Viol d'Orchestre (2 rks)

8 Salicional (2 rks)

8 French Horn

8 Oboe Horn

8 Quintadena

8 Lieblich Flute

8 Concert Flute

8 Spitz Flute (2 rks)

8 Vox Humana

8 Vox Humana

8 Dulciana (2 rks)

4 Octave Open

4 Octave Horn

4 Piccolo M

4 Solo String (2 rks)

4 Gambette (2 rks)

4 Cello (2 rks)

4 Viol (2 rks)

4 Salicet (2 rks)

4 Lieblich Flute

4 Concert Flute

4 Spitz Flute (2 rks)

4 Vox Humana

4 Vox Humana

4 Dulcet (2 rks)

2 2/3 Lieblich Twelfth

2 2/3 Twelfth

2 Lieblich Piccolo

2 Piccolo

8 Piano

Wood Harp Sub

Wood Harp

Metal Harp

Chrysoglott

Snare Drum

Castanets

Tambourine

Wood Block

Tom-Tom

Hi Hat

Tap Cymbal

Brush Cymbal

Octave

Solo to Accomp

MIDI on Accomp

GREAT

16 Double English Horn

16 Bombarde

16 Solo Trumpet (Ten C)

16 Chorus Trumpet (Ten C)

16 Ophicleide

16 Diaphone

16 Open Diapason (Ten C)

16 Diaphonic Horn

16 Tibia Clausa

16 Tibia Clausa (Ten C)

16 Tibia Clausa

16 Clarinet

16 Orchestral Oboe (Ten C)

16 Musette (Ten C)

16 Saxophone (Ten C)

16 Solo String (2 rks)

16 Gamba (2 rks)

16 Cello (2 rks)

16 Minor Strings (4 rks)

16 Krumet (Ten C)

16 Cor Anglais (Ten C)

16 Oboe Horn

16 Quintadena (Ten C)

16 Bourdon

16 Vox Humana (Ten C)

16 Vox Humana (Ten C)

16 Dulciana (2 rks)

8 English Horn

8 Tuba Mirabilis

8 Solo Trumpet

8 Chorus Trumpet

8 Tuba Horn

8 Diaphonic Diapason

8 Open Diapason

8 Horn Diapason

8 Tibia Clausa

8 Tibia Clausa

8 Tibia Clausa

8 Clarinet

8 Kinura

8 Orchestral Oboe

8 Musette

8 Saxophone

8 Solo String (2 rks)

8 Gamba (2 rks)

8 Cello (2 rks)

8 Viol d'Orchestre (2 rks)

8 Salicional (2 rrks)

8 Krumet

8 Cor Anglais

8 French Horn

8 Oboe Horn

8 Quintadena

8 Lieblich Flute

8 Concert Flute

8 Spitz Flute (2 rks)

8 Vox Humana

8 Vox Humana

8 Dulciana (2 rks)

5 1/3 Fifth (Tibia S)

5 1/3 Fifth (Tibia M)

4 Octave

4 Octave Open

4 Octave Horn

4 Piccolo

4 Piccolo

4 Piccolo

4 Solo String (2 rks)

4 Gambette (2 rks)

4 Cello (2 rks)

4 Viol (2 rks)

4 Salicet (2 rks)

4 Harmonic Flute

4 Lieblich Flute

4 Spitz Flute (2 rks)

4 Dulcet (2 rks)

3 1/5 Tenth (Tibia M)

2 2/3 Twelfth (Tibia S)

2 2/3 Twelfth (Tibia M)

2 2/3 Lieblich Twelfth

2 Piccolo (Tibia)

2 Piccolo (Tibia)

2 Piccolo (Tibia)

2 Fifteenth

2 Lieblich Piccolo

1 3/5 Lieblich Tierce

1 Lieblich Fife

8 Piano

4 Piano

Wood Harp Sub

Wood Harp

Xylophone Sub

Xylophone

Glockenspiel

Chrysoglott

Sub Octave

Unison Off

Octave

Solo on Great

MIDI on Great

ORCHESTRAL

16 Double English Horn

16 Solo Trumpet (Ten C)

16 Ophicleide

16 Tibia Clausa

16 Tibia Clausa (Ten C)

16 Tibia Clausa

16 Saxophone (Ten C)

16 Major Strings (4 rks)

16 Minor Strings (6 rks)

16 Vox Humana (Ten C)

16 Vox Humana (Ten C)

8 English Horn

8 Tuba Mirabilis

8 Solo Trumpet

8 Chorus Trumpet

8 Style D Trumpet

8 Tuba Horn

8 Open Diapason

8 Horn Diapason

8 Tibia Clausa

8 Tibia Clausa

8 Tibia Clausa

8 Clarinet

8 Orchestral Oboe

8 Musette

8 Saxophone

8 Solo String (2 rks)

8 Gamba (2 rks)

8 Cello (2 rks)

8 Minor Strings (4 rks)

8 Krumet

8 Cor Anglais

8 French Horn

8 Vox Humana

8 Vox Humana

4 Piccolo

4 Piccolo

4 Piccolo

4 Solo String (2 rks)

4 Mezzo Strings (4 rks)

4 Minor Strings (4 rks)

4 Harmonic Flute

2 2/3 Twelfth (Tibia S)

2 2/3 Twelfth (Tibia M)

2 Piccolo (Tibia S)

2 Piccolo (Tibia M)

1 3/5 Tierce (Tibia M)

8 Piano

Wood Harp

Xylophone

Glockenspiel

Metal Harp

Vibraharp

Chrysoglott

Sub Octave

Unison Off

Octave

Solo on Orch

MIDI on Orch

ANCILLARY

8 Principal

4 Octave

2 Superoctave

Mixture IV

8 Fanfare Trumpet

BOMBARDE

16 Double English Horn

8 English Horn

8 Tuba Mirabilis

8 Solo Trumpet

8 Chorus Trumpet

8 Style D Trumpet

8 Tuba Horn

8 Diaphonic Diapason

8 Open Diapason

8 Tibia Clausa

8 Tibia Clausa

8 Tibia Clausa

8 Saxophone

8 Major Strings (4 rks)

8 Minor Strings (6 rks)

8 Vox Humana

8 Vox Humana

4 Piccolo

4 Piccolo

4 Piccolo

4 Major Strings (4 rks)

4 Minor Strings (6 rks)

2 2/3 Twelfth (Tibia S)

2 2/3 Twelfth (Tibia M)

2 Piccolo (Tibia)

2 Piccolo (Tibia)

2 Piccolo (Tibia)

1 Fife (Tibia M)

8 Piano

Xylophone

Glockenspiel

Vibraharp

Chrysoglott

Sub Octave

Unison Off

Octave

Great to Bombarde

Great Octave Bombarde

Orch to Bombarde

Solo on Bombarde

MIDI on Bombarde

SOLO

8 Fanfare Trumpet

8 English Horn

8 Tuba Mirabilis

8 Solo Trumpet

8 Chorus Trumpet

8 Style D Trumpet

8 Tuba Horn

8 Diaphonic Diapason

8 Open Diapason

8 Tibia Clausa

8 Tibia Clausa

8 Tibia Clausa

8 Clarinet

8 Kinura

8 Orchestral Oboe

8 Musette

8 Saxophone

8 Major Strings (4 rks)

8 Minor Strings (6 rks)

8 Krumet

8 Cor Anglais

8 French Horn

8 Oboe Horn

8 Vox Humana

8 Vox Humana

8 Piccolo

4 Piccolo

4 Piccolo

4 Harmonic Flute

2 2/3 Twelfth (Tibia S)

2 2/3 Twelfth (Tibia M)

2 Piccolo (Tibia)

2 Piccolo (Tibia)

2 Piccolo (Tibia)

1 3/5 Tierce (Tibia S)

1 3/5 Tierce (Tibia M)

1 1/3 Larigot (Tibia M)

Sub Octave

Unison Off

Octave

MIDI on Solo

8 Piano

Wood Harp Sub

Xylophone

Glockenspiel

Metal Harp

Vibraharp

Cathedral Chimes

ACCOMP 2nd Touch

8 English Horn

8 Tuba Mirabilis

8 Solo Trumpet

8 Chorus Trumpet

8 Tuba Horn

8 Diaphonic Diapason

8 Tibia Clausa S

8 Tibia Clausa M

8 Clarinet

8 French Horn

4 Piccolo (2 rks)

Glockenspiel Octave

Cathedral Chimes

Percussions 2nd Touch

Traps 2nd Touch

Great Octave Accomp

Solo on Accomp

MIDI on Accomp

GREAT 2nd Touch

English Horn 16-8

Solo on Great

Solo on Great PIZZ

MIDI on Great

TREMULANTS

Main

Main Strings

Clarinet

Tibias/Sax/Voxes

Solo

Solo Strings

Tubas

Trumpets

English Horn

KEY CHEEK PISTONS

Unisons Off

Celestes Off

Main Vox 1 Off

Main Vox 2 On

Solo Vox 1 Off

Solo Vox 2 On

Chorus Trumpet Off

Style D Trumpet On

Quintadena Celeste

Horn Diapason Celeste

Master Expression

Marimba Re-it

Chrysoglott Motor

Vibraharp Motor

Ancillary on Solo

Ancillary on Orch

Ancillary on Bombarde

Ancillary on Great

Ancillary on Accomp

Ancillary on Pedal

TOE PISTON EFFECTS

Persian Cymbal

Gong

Wind Chimes

Train

Birds

CHAMBER ANALYSIS

MAIN

1 Chorus Trumpet 8

2 Tuba Horn 16-4

3 "D" Trumpet 8

4 Diaphonic Diapason 32-4

5 Open Diapason 8-4

6 Tibia Clausa 16-2

7 Clarinet 16-8

8 Musette 8

9 Cor Anglais 8

10 Gamba 8-4

11 Gamba Celeste 8-4

12 Viol d'Orchestra 8-2

13 Viol Celeste 8-4

14 Salicional 8-2

15 Salicional Celeste 8-4

16 Oboe Horn 16-8

17 Harmonic Flute 4

18 Concert Flute 16-4

19 Dulciana 16-4

20 Dulciana Celeste 16-4

21 Vox Humana 8-4

22 Vox Humana #2 8-4

23 Violone (Pedal) 32-16

Chrysoglott

SOLO

32 English Posthorn 16-8

33 Tuba Mirabilis 16-8

34 Brass Trumpet 8

35 Horn Diapason/Diaphone 16-4

36 Horn Diapason Celeste 8-4

37 Tibia Clausa 32-2

38 Brass Saxophone 8

39 Orchestral Oboe 8

40 Kinura 8

41 Krumet 8

42 Solo String 16-4

43 Solo String Celeste 8-4

44 Cello 8-4

45 Cello Celeste 8-4

46 French Horn 8

47 Quintadena 8

48 Quintadena Celeste 8

49 Lieblich Flute 8-2

50-51 Spitzflute Celeste II 8-4

52 Vox Humana 8-4

53 Vox Humana #2 8-4

ANCILLARY

24 Principal 8

25 Octave 4

26 Superoctave 2

27-30 Mixture IV

31 Trompette en-chamade 8

PERCUSSION

54 Tibia Clausa 8-2

55 8' Pedal Tibia Pizzicato

Piano

Wood Harp

Wood Harp Re-it

Metal Harp

Vibraharp

Xylophone

Glockenspiel

Chimes

TRAPS

Bass Drum

Tympani

Crash Cymbal

Tap Cymbal

Brush Cymbal

Finger Cymbals

Choke Cymbal

Wood Block

Tambourine

Castanets

Tom-tom

Snare Drum

SOUND EFFECTS

Persian Cymbal

Train

Wind Chimes

Birds

Gong

ALLEN EXPRESSION / CRESCENDO PEDALS

EXPRESSION SHOE CAGE

PREMIUM KEYBOARDS

The Allen keyboard utilizes sealed contacts and wood keysticks to provide the ultimate in touch and control. The level of quality and adjustability of Allen keyboards makes them the envy of the industry and the choice of discerning musicians.

KEY CONTACT

The key contact, while unseen, is an important part of any church organ. If one fails during a performance, the entire musical program can be compromised. Allen introduced a maintenance-free system in which a sealed reed switch is engaged by magnet. Neither dust nor the environment will compromise your music program with an Allen Organ.

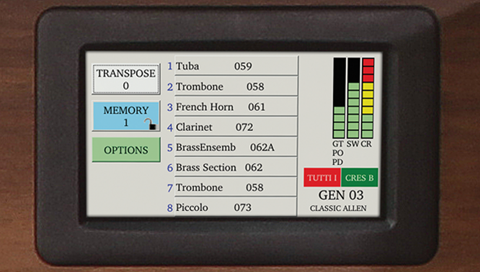

GENISYS™ Voices provide the tonal diversity of a comprehensive stop list to even the most modest instruments. GENISYS Voices set a new standard for organist-friendly operation and include sounds that enhance every style of worship and organ literature!

STR-4X SPECIFICATIONS

Featuring Two Complete Voicings

32 Theatre Ranks

Solo

Tuba Mirabilis

English Posthorn

Brass Trumpet

Horn Diapason

Horn Diapason Celeste

Solo Tibia Clausa

Kinura

Orchestral Oboe

Krumet

Saxophone

Solo String

Solo String Celeste

Quintadena

Lieblich Flute

Solo Vox Humana

Main

Tuba Horn

"D" Trumpet

Open Diapason

Main Tibia Clausa

Clarinet

Musette

Violin

Violin Celeste

Gamba

Gamba Celeste

Gemshorn

Gemshorn Celeste

Oboe Horn

Concert Flute

Main Vox Humana

Chrysoglott

Percussion

Pedal Pizz. Tibia Clausa

Morton Tibia Clausa

Piano

Glockenspiel

Xylophone

Wood Harp/Marimba

Vibraphone

Solo Chrysoglott

Chimes

Bass Drum

Snare Drum Roll

Tambourine

Castanets

Tom-Tom

Wood Block

Tap Cymbal

Brush Cymbal

Triangle

Choke Cymbal

Splash Cymbal

Persian (roll) Cymbal

Crash Cymbal

Tuned Tympani

Tympani Roll

Auto Horn

Birds

Gong

Siren

Wind Chimes

Train Whistle

STR-4X

Pedal

32 Contra Diaphone C. Bomb

32 Contra Tibia Clausa

16 Bombarde

16 Double English Horn

16 Ophicleide

16 Diaphone

16 Diaphonic Horn

16 Solo Tibia Clausa

16 Bass Clarinet

16 Contra Gamba 2 Rks

16 Oboe Horn

16 Bourdon

16 Gemshorn 2 Rks

8 Tuba Mirabilis

8 English Horn

8 Tuba Horn

8 Open Diapason

8 Horn Diapason

8 Solo Tibia Clausa

8 Tibia Clausa

8 Tibia Clausa Pizz.

8 Clarinet

8 Cello 2 Rks

8 Flute

Accomp. to Pedal

Great to Pedal

Solo to Pedal

MIDI on Pedal

16 Piano Open Diap.

Bass Drum

Tympani

Crash Cymbal Mixture III

Tap Cymbal

Brush Cymbal

Sound Effects

Splash Cymbal

Wind Chimes

Gong

Birds

Auto Horn

Siren

Train Whistle

Accompaniment

8 Tuba Mirabilis

8 English Horn

8 Trumpet

8 Style D Trumpet

8 Tuba Horn

8 Open Diapason

8 Horn Diapason

8 Solo Tibia Clausa

8 Tibia Clausa

8 Clarinet

8 Solo Sting 2 Rks

8 Violin 2 Rks

8 Gamba 2 Rks

8 Oboe Horn

8 Quintadena

8 Lieblich Flute

8 Concert Flute

8 Vox Humana (S)

8 Vox Humana

4 Octave

4 Octave Horn

4 Piccolo

4 Solo String 2 Rks

4 Viol 2 Rks

4 Gambette 2 Rks

4 Lieblich Flute

4 Concert Flute

4 Vox Humana (M)

2 2/3 Twelfth

2 Piccolo

Octave

Solo on Accomp. Bombarde

MIDI on Accomp.

8 Piano Open Diap.

Harp Sub Mixture IV

Harp Scharf IV

Solo Chrysoglott

Chrysoglott Mixture III

Snare Drum

Castanets

Tambourine

Wood Block

Tom-Tom

Choke Cymbal

Tap Cymbal

Brush Cymbal

Triangle

Accomp. 2nd Touch

8 Tuba Mirabilis

8 English Horn

8 Trumpet

8 Style D Trumpet

8 Tuba Horn

8 Open Diapason

8 Solo Tibia Clausa

8 Clarinet

4 Piccolos

Octave Glockenspiel

Octave 4

Cathedral Chimes

Perc Second Touch

Traps Second Touch

Great Octave to Accomp.

Solo to Accomp.

MIDI on Accomp. 2nd

Solo

8 Tuba Mirabilis

8 English Horn

8 Trumpet

8 Style D Trumpet

8 Tuba Horn

8 Open Diapason

8 Horn Diapason

8 Solo Tibia Clausa

8 Tibia Clausa

8 Clarinet

8 Kinura Clarion 4

8 Orchestral Oboe

8 Musette French Horn

8 Krumet

8 Saxophone

8 Solo String 2 Rks

8 Violin 2 Rks

8 Gamba 2 Rks

8 Quintadena

8 Lieblich Flute

8 Vox Humana (S)

8 Vox Humana

4 Solo Piccolo

4 Piccolo

2 2/3 Solo Twelfth

2 Solo Piccolo

2 Piccolo

1 3/5 Solo Tierce

1 1/3 Solo Larigot

Sub Octave

Unison Off

Octave

6 2/5 Solo Third

5 1/3 Solo Fifth

MIDI on Solo

8 Piano Open Diap.

Glockenspiel Octave 4

Xylophone Fifteenth 2

Harp Sub Mixture IV

Vibraharp Plein Jeu IV

Chrysoglott Sub Mixture III

Cathedral Chimes

Great

16 Bombarde

16 Double English Horn

16 Trumpet (Ten C)

16 Ophicleide

16 Diaphone

16 Diaphonic Horn

16 Solo Tibia Clausa

16 Tibia Clausa (Ten C)

16 Clarinet

16 Orchestral Oboe (Ten C)

16 Musette (Ten C) French Horn

16 Krumet (Ten C)

16 Saxophone (Ten C)

16 Solo String 2 Rks

16 Violin 2 Rks

16 Gamba 2 Rks

16 Oboe Horn

16 Bourdon

16 Vox Humana (S) (Ten C)

16 Vox Humana (Ten C)

8 Tuba Mirabilis

8 English Horn

8 Trumpet

8 Tuba Horn

8 Open Diapason

8 Horn Diapason

8 Solo Tibia Clausa

8 Tibia Clausa

8 Clarinet

8 Kinura Clarion 4

8 Orchestral Oboe

8 Musette French Horn

8 Krumet

8 Saxophone

8 Solo String 2 Rks

8 Violin 2 Rks

8 Gamba 2 Rks

8 Oboe Horn

8 Quintadena

8 Lieblich Flute

8 Concert Flute

8 Vox Humana (S)

8 Vox Humana

5 1/3 Fifth (Tibia)

4 Octave

4 Octave (Horn)

4 Solo Piccolo

4 Piccolo

4 Solo String 2 Rks

4 Viol 2 Rks

4 Gambette 2 Rks

4 Lieblich Flute

4 Concert Flute

3 1/5 Lieblich Tenth Plein Jeu IV

2 2/3 Solo Twelfth

2 2/3 Twelfth

2 Solo Piccolo

2 Piccolo

2 Fifteenth

2 Piccolo

1 Fife (Lieb)

Sub Octave

Unison Off

Octave

Solo on Great

MIDI on Great

8 Piano Open Diap.

Glockenspiel Octave 4

Xylophone Fifteenth 2

Harp Mixture IV

Chrysoglott Mixture III

Great 2nd Touch

16 Double English Horn

8 English Horn

Solo on Great

Solo on Great Pizz.

MIDI on Great 2nd

Bombarde

16 Bombarde

16 Double English Horn

16 Trumpet (Ten C)

16 Ophicleide

16 Diaphone

16 Solo Tibia Clausa

16 Tibia Clausa (Ten C)

16 Krumet (Ten C)

16 Saxophone (Ten C) Clarion 4

16 String Ensemble 6 Rks

16 Vox Humana (S) (Ten C)

16 Vox Humana (Ten C)

8 Tuba Mirabilis

8 English Horn

8 Trumpet

8 Tuba Horn

8 Open Diapason

8 Solo Tibia Clausa

8 Tibia Clausa

8 Krumet

8 Saxophone

8 Solo String 2 Rks

8 Violin 2 Rks

8 Gamba 2 Rks

8 Vox Humana (S)

8 Vox Humana

4 Solo Piccolo

4 Piccolo

4 String Ensemble 6 Rks

2 2/3 Solo Twelfth

2 Solo Piccolo

2 Piccolo

Sub Octave

Octave

Great to Bombarde

Great Octave Bombarde

Solo on Bombarde

MIDI on Bombarde

8 Piano Open Diap.

Glockenspiel Octave 4

Xylophone Fifteenth 2

Harp Mixture IV

Solo Chrysoglott Plein Jeu IV

Chrysoglott Mixture III

Tremulants

Main

Main Strings

Clarinet

Solo

Solo Strings

Tibias

Voxes

Tuba Horn

Tuba Mirabilis

English Horn

Pistons

Great Solo Tibia Off

Great Morton Tibia On

Bombarde Solo Tibia Off

Bombarde Morton Tibia On

Acc./Solo/String>Gems

Great/Solo/String>Gems

So > Gt Melody Coupler

Horn Diapason Celeste On

Marimba Re-it

String Celeste Off

Great Tuba Horn Off

Great Style D Trumpet On

Bombarde Tuba Horn Off

Bombarde Style D Trumpet On

Percussion > Master Expression

Main > Master Expression

32 Contra Tibia (Toe Stud)

Walter Strony is one of America's premier concert organists. He has established himself as one of those few organists equally at home playing both theatre and classical organ.

Walt has performed hundreds of concerts worldwide, including many conventions of the American Theatre Organ Society and the American Guild of Organists. He has twice been voted "Organist of the Year" by the ATOS - the only living theatre organist to have received that honor. In 1999, he made his premiere appearance with the Calgary Philharmonic Orchestra.

Walt was inducted into the ATOS Hall of Fame and is also well known for his many fine recordings. His services as a pipe and digital organ consultant are always in demand in addition to his prowess as a concert artist.

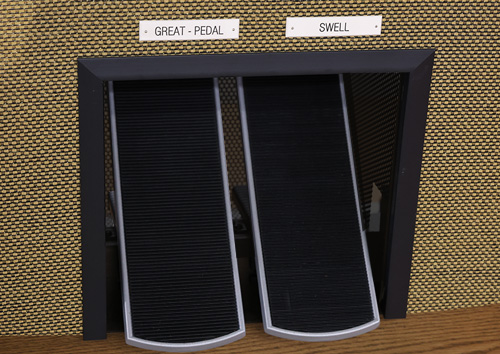

ALLEN EXPRESSION / CRESCENDO PEDALS

EXPRESSION SHOE CAGE

GENISYS™ Voices provide the tonal diversity of a comprehensive stop list to even the most modest instruments. GENISYS Voices set a new standard for organist-friendly operation and include sounds that enhance every style of worship and organ literature!

TX323 SPECIFICATIONS

Featuring multiple organ Stop Lists: Morton, Wurlitzer, Barton

PEDAL

32 CONTRA VIOLONE

16 OPHICLEIDE

16 DIAPHONE

16 VIOLONE

16 BOURDON

8 ENGLISH POST HORN

8 TRUMPET

8 OPEN DIAPASON

8 SOLO TIBIA CLAUSA

8 TIBIA CLAUSA (PIZZ.)

8 CLARINET

8 FLUTE

16 PIANO

8 PIANO

ACCOMPANIMENT TO PEDAL

BASS DRUM

TAP CYMBAL (BRUSH)

GENISYS VOICE 1

GENISYS VOICE 2

ACCOMPANIMENT

8 ENGLISH POST HORN

8 BRASS TRUMPET

8 TUBA MIRABILIS

8 TRUMPET

8 OPEN DIAPASON

8 TIBIA CLAUSA (m)

8 CLARINET

8 VIOLINS 3 RKS

8 OBOE HORN

8 QUINTADENA

8 CONCERT FLUTE

8 VOX HUMANA

4 OCTAVE

4 PICCOLO (m)

4 CONCERT FLUTE

ACC VIOLINS>DOLCES

OCTAVE

8 PIANO

HARP SUB

HARP

CHRYSOGLOTT

SNARE DRUM

TOM-TOM (CASTANETS)

HI-HAT (TAMBOURINE)

TAP CYMBAL (BRUSH)

ALTERNATE TRAPS

TRAPS TO 2ND T

GENISYS VOICE 3

GENISYS VOICE 4

GREAT

16 ENGLISH POST HORN

16 BRASS TRUMPET (ten c)

16 BOMARDE

16 DIAPHONE

16 SOLO TIBIA CLAUSA (ten c)

16 TIBIA CLAUSA (ten c)

16 CLARINET

16 KRUMET (ten c)

16 ORCHESTRAL OBOE (ten c)

16 SAXAPHONE (ten c)

16 VIOLINS 3 RKS (ten c)

16 VOX HUMANA (ten c)

8 ENGLISH POST HORN

8 BRASS TRUMPET

8 TUBA MIRABILIS

8 TRUMPET

8 OPEN DIAPASON

8 SOLO TIBIA CLAUSA

8 TIBIA CLAUSA

8 CLARINET

8 KRUMET

8 ORCHESTRAL OBOE

8 SAXOPHONE

8 VIOLINS 3 RKS

8 QUINTADENA

8 CONCERT FLUTE

8 VOX HUMANA

5 1/3 FIFTH (TIBIA)

4 OCTAVE

4 SOLO PICCOLO

4 PICCOLO

4 VIOLINS 3 RKS

4 FLUTE

2 2/3 TWELFTH

2 SOLO PICCOLO

2 PICCOLO

2 FIFTEENTH

1 FIFE (FLUTE)

XYLOPHONE

GLOCKENSPIEL

SUB OCTAVE

OCTAVE

SOLO SUB GREAT

SOLO TO GREAT

GENISYS VOICE 5

GENISYS VOICE 6

SOLO

8 ENGLISH POST HORN

8 BRASS TRUMPET

8 TUBA MIRABILIS

8 TRUMPET

8 OPEN DIAPASON

8 SOLO TIBIA CLAUSA

8 TIBIA CLAUSA

8 CLARINET

8 KRUMET

8 ORCHESTRAL OBOE

8 SAXAPHONE

8 VIOLINS 3 RKS

8 CONCERT FLUTE

8 VOX HUMANA

4 SOLO PICCOLO

4 PICCOLO

2 2/3 TWELFTH

2 SOLO PICCOLO

1 3/5 TIERCE

SUB OCTAVE

8 PIANO

HARP SUB

CHRYSOGLOTT

VIBRAPHONE

XYLOPHONE

GLOCKENSPIEL

GENISYS VOICE 7

GENISYS VOICE 8

ACCOMPANIMENT 2ND TOUCH

8 ENGLISH POST HORN

8 BRASS TRUMPET

8 TUBA MIRABILIS

8 TRUMPET

8 SOLO TIBIA CLAUSA

8 CLARINET

GREAT OCTAVE ACC

SOLO TO ACC

PERC ON 2ND

GENISYS VOICE 9

GENISYS VOICE 10

GREAT 2ND TOUCH

16-8 ENLGLISH POST HORN

SOLO TO GREAT

SOLO TO GREAT-PIZZ

GENISYS VOICE 11

GENISYS VOICE 12

TX323

Classical Suite

PEDAL

32 CONTRA VIOLONE

16 POSAUNE

16 DIAPASON

16 VIOLONE

16 BOURDON

8 FRENCH TROMPETTE

8 TROMBA

8 OCTAVE

8 GEDACKT

8 CROMORNE

8 HARMONIC FLUTE

4 CHORALBASS

MIXTURE III

GREAT TO PEDAL

ACCOMPANIMENT

8 FRENCH TROMPETTE

8 TROMPETE

8 TROMBA

8 TRUMPET

8 PRINCIPAL

8 GEDACKT

8 CROMORNE

8 VIOLAS III

8 OBOE HORN

8 QUINTADENA

8 HARMONIC FLUTE

8 VOX HUMANA

4 OCTAVE

4 GEDACKT

4 HARMONIC FLUTE

MIXTURE IV

GREAT

16 FRENCH TROMPETTE

16 TROMPETE

16 TROMBA

16 DIAPASON

16 BOURDON

16 GEDACKT

16 CROMORNE

16 KRUMET

16 BASSON

16 ENGLISH HORN

16 VIOLAS III

16 VOX HUMANA

8 FRENCH TROMPETTE

8 TROMPETE

8 TROMBA

8 TRUMPET

8 PRINCIPAL

8 BOURDON

8 GEDACKT

8 CROMORNE

8 KRUMET

8 HAUTBOIS

8 ENGLISH HORN

8 VIOLAS III

8 QUINTADENA

8 HARMONIC FLUTE

8 VOX HUMANA

5 1/3 QUINTFLÖTE

4 OCTAVE

4 BOURDON

4 GEDACKT

4 VIOLAS III

4 HARMONIC FLUTE

2 2/3 TWELFTH

2 PICCOLO

2 FIFTEENTH (PRIN)

1 FIFE

MIXTURE IV

MIXTURE III

SOLO

8 FRENCH TROMPETTE

8 TROMPETE

8 TROMBA

8 TRUMPET

8 PRINCIPAL

8 BOURDON

8 GEDACKT

8 CROMORNE

8 KRUMET

8 HAUTBOIS

8 ENGLISH HORN

8 VIOLAS III

8 HARMONIC FLUTE

8 VOX HUMANA

4 BOURDON

4 GEDACKT

2 2/3 NASARD

2 PICCOLO

1 3/5 TIERCE

MIXTURE IV

MIXTURE III

ACCOMPANIMENT 2ND TOUCH

8 ENGLISH POST HORN

8 BRASS TRUMPET

8 TUBA MIRABILIS

8 TRUMPET

8 SOLO TIBIA CLAUSA

8 CLARINET

GREAT OCTAVE ACC

SOLO TO ACC

PERC ON 2ND

GREAT 2ND TOUCH

8 FRENCH TROMPETTE

GENISYS™ Voices provide the tonal diversity of a comprehensive stop list to even the most modest instruments. GENISYS Voices set a new standard for organist-friendly operation and include sounds that enhance every style of worship and organ literature!

ALLEN EXPRESSION / CRESCENDO PEDALS

EXPRESSION SHOE CAGE

TX317 SPECIFICATIONS

Featuring multiple organ Stop Lists: Morton, Wurlitzer, Barton

PEDAL

16 OPHICLEIDE

16 DIAPHONE

16 TIBIA CLAUSA

16 VIOLONE

8 ENGLISH POST HORN

8 TUBA HORN

8 OPEN DIAPASON

8 TIBIA CLAUSA (PIZZ.)

8 TIBIA CLAUSA

8 CLARINET

8 FLUTE

ACCOMPANIMENT TO PEDAL

GENISYS VOICE 1

GENISYS VOICE 2

MIDI ON PEDAL

BASS DRUM

TAP CYMBAL (BRUSH)

ACCOMPANIMENT

8 ENGLISH POST HORN

8 TUBA HORN

8 OPEN DIAPASON

8 TIBIA CLAUSA

8 CLARINET

8 VIOLINS 2 RKS

8 QUINTADENA

8 CONCERT FLUTE

8 VOX HUMANA

4 OCTAVE

4 PICCOLO

4 VIOLINS 2 RKS

4 CONCERT FLUTE

CHRYSOGLOTT

SNARE DRUM

TOM-TOM (CASTANETS)

COW BELL (WOOD BLOCK)

HI-HAT (TAMBOURINE)

TAP CYMBAL (BRUSH)

ALTERNATE TRAPS

TRAPS TO 2ND T

GENISYS VOICE 3

GENISYS VOICE 4

MIDI ON ACCOMPANIMENT

GREAT

16 ENGLISH POST HORN

16 TUBA HORN

16 DIAPHONE

16 TIBIA CLAUSA

16 CLARINET

16 ORCHESTRAL OBOE

16 VIOLINS 2 RKS

16 VOX HUMANA

8 ENGLISH POST HORN

8 TUBA HORN

8 OPEN DIAPASON

8 TIBIA CLAUSA

8 CLARINET

8 KINURA

8 ORCHESTRAL OBOE

8 VIOLINS 2 RKS

8 VOX HUMANA

8 VIOLINS 2 RKS

8 QUINTADENA

8 CONCERT FLUTE

8 VOX HUMANA

5 1/3 FIFTH (TIBIA)

4 OCTAVE

4 PICCOLO

4 VIOLINS 2 RKS

2 2/3 TWELFTH

2 PICCOLO

1 FIFE (FLUTE)

GLOCKENSPIEL

XYLOPHONE

SOLO TO GREAT

SOLO TO GREAT PIZZ.

GENISYS VOICE 5

GENISYS VOICE 6

MIDI ON GREAT

SOLO

8 ENGLISH POST HORN

8 TUBA HORN

8 OPEN DIAPASON

8 TIBIA CLAUSA

8 CLARINET

8 KINURA

8 ORCHESTRAL OBOE

8 VIOLINS 2 RKS

8 VOX HUMANA

4 PICCOLO

2 2/3 TWELFTH

2 PICCOLO

1 3/5 TIERCE

SUB OCTAVE

SUB-CHRYSOGLOTT

GLOCKENSPIEL

XYLOPHONE

CATHEDRAL CHIMES

GENISYS VOICE 7

GENISYS VOICE 8

MIDI ON SOLO

TX317

Classical Suite

PEDAL

16 POSAUNE

16 DIAPASON

16 GEDACKT

16 VIOLONE

8 FRENCH TRUMPETTE

8 OCTAVE

8 GEDACKT

8 CROMORNE

8 HARMONIC FLUTE

MIXTURE III

GREAT TO PEDAL

ACCOMPANIMENT

8 FRENCH TROMPETTE

8 PRINCIPAL

8 GEDACKT

8 CROMORNE

8 VIOLAS II

8 QUINTADENA

8 HARMONIC FLUTE

8 VOX HUMANA

4 OCTAVE

4 GEDACKT

4 HARMONIC FLUTE

GREAT

16 FRENCH TROMPETTE

16 DIAPASON

16 GEDACKT

16 CROMORNE

16 BASSON

16 VIOLAS II

16 VOX HUMANA

8 FRENCH TROMPETT

8 PRINCIPAL

8 GEDACKT

8 CROMORNE

8 HAUTBOIS

8 VIOLAS II

8 QUINTADENA

8 HARMONIC FLUTE

8 VOX HUMANA

5 1/3 QUINTFLÖTE

4 OCTAVE

4 GEDACKT

4 VIOLAS II

2 2/3 TWELFTH

2 PICCOLO

1 FIFE

MIXTURE III

MIXTURE IV

SOLO

8 FRENCH TROMPETTE

8 PRINCIPAL

8 GEDACKT

8 CROMORNE

8 HAUTBOIS

8 VIOLAS II

8 VOX HUMANA

8 GEDACKT

8 CROMORNE

8 KINURA

8 HAUTBOIS

8 VIOLAS II

8 VOX HUMANA

4 GEDACKT

2 2/3 NASARD

2 PICCOLO

1 3/5 TIERCE

MIXTURE III

MIXTURE IV

ACCOMPANIMENT 2ND TOUCH

8 FRENCH TROMPETTE

8 CROMORNE

ALLEN EXPRESSION / CRESCENDO PEDALS

EXPRESSION SHOE CAGE

GENISYS™ Voices provide the tonal diversity of a comprehensive stop list to even the most modest instruments. GENISYS Voices set a new standard for organist-friendly operation and include sounds that enhance every style of worship and organ literature!

TX217 SPECIFICATIONS

Featuring multiple organ Stop Lists: Morton, Wurlitzer, Barton

PEDAL

16 OPHICLEIDE

16 DIAPHONE

16 TIBIA CLAUSA

16 VIOLONE

8 ENGLISH POST HORN

8 TUBA HORN

8 OPEN DIAPASON

8 TIBIA CLAUSA (PIZZ.)

8 TIBIA CLAUSA

8 CLARINET

8 FLUTE

ACCOMPANIMENT TO PEDAL

MIDI ON PEDAL

GENISYS VOICE 1

GENISYS VOICE 2

BASS DRUM

TAP CYMBAL

ACCOMPANIMENT

8 ENGLISH POST HORN

8 TUBA HORN

8 OPEN DIAPASON

8 TIBIA CLAUSA

8 CLARINET

8 VIOLINS 2 RKS

8 QUINTADENA

8 CONCERT FLUTE

8 VOX HUMANA

4 OCTAVE

4 PICCOLO

4 VIOLINS 2 RKS

4 CONCERT FLUTE

CHRYSOGLOTT

SNARE DRUM

TOM-TOM

TAMBOURINE

TAP CYMBAL

GENISYS VOICE 3

GENISYS VOICE 4

MIDI ON ACCOMPANIMENT

SOLO

16 ENGLISH POST HORN

16 TUBA HORN

16 DIAPHONE

16 TIBIA CLAUSA

16 CLARINET

16 ORCHESTRAL OBOE

16 VIOLINS 2 RKS

16 VOX HUMANA

8 ENGLISH POST HORN

8 TUBA HORN

8 OPEN DIAPASON

8 TIBIA CLAUSA

8 CLARINET

8 KINURA

8 ORCHESTRAL OBOE

8 VIOLINS 2 RKS

8 VOX HUMANA

5 1/3 FIFTH (TIBIA)

4 OCTAVE

4 PICCOLO

4 VIOLINS 2 RKS

2 2/3 TWELFTH

2 PICCOLO

1 3/5 TIERCE

GLOCKENSPIEL

XYLOPHONE

CATHEDRAL CHIMES

GENISYS VOICE 5

GENISYS VOICE 6

MIDI ON SOLO

TREMULANTS

MAIN

SOLO

TIBIA/VOX

EFFECTS

PERSIAN CYMBAL

SIREN

TRAIN WHISTLE

HORN

BELL TREE

BIRD

TX217

Classical Suite

PEDAL

16 OPHICLEIDE

16 DIAPASON

16 TIBIA

16 VIOLONE

8 HORN

8 TUBA

8 OPEN DIAPASON

8 PIZZACATO

8 TIBIA

8 CLARINET

8 FLUTE

ACCOMPANIMENT TO PEDAL

MIDI ON PEDAL

GENISYS VOICE 1

GENISYS VOICE 2

MIXTURE III

SOLO TO PEDAL

ACCOMPANIMENT

8 HORN

8 TUBA

8 OPEN DIAPASON

8 TIBIA

8 CLARINET

8 CELLO

8 QUINTADENA

8 FLUTE

8 VOX HUMANA

4 OCTAVE

4 PICCALO

4 CELLO

4 FLUTE

MIXTURE IV

SNARE DRUM

TOM-TOM

TAMBOURINE

TAP CYMBAL

GENISYS VOICE 3

GENISYS VOICE 4

MIDI ON ACCOMPANIMENT

SOLO

16 HORN

16 TUBA

16 DIAPASON

16 TIBIA

16 CLARINET

16 OBOE

16 CELLO

16 VOX HUMANA

8 HORN

8 TUBA

8 OPEN DIAPASON

8 TIBIA

8 CLARINET

8 KINURA

8 OBOE

8 CELLO

8 VOX HUMANA

5 1/3 FIFTH

4 OCTAVE

4 PICCOLO

4 CELLO

2 2/3 TWELFTH

2 PICCOLO

1 3/5 TIERCE

MIXTURE III

MIXTURE IV

CATHEDRAL CHIMES

GENISYS VOICE 5

GENISYS VOICE 6

MIDI ON SOLO

TREMULANTS

MAIN

SOLO

TIBIA/VOX

EFFECTS

PERSIAN CYMBAL

SIREN

TRAIN WHISTLE

HORN

BELL TREE

BIRD

GENISYS™ Voices provide the tonal diversity of a comprehensive stop list to even the most modest instruments. GENISYS Voices set a new standard for organist-friendly operation and include sounds that enhance every style of worship and organ literature!

ALLEN EXPRESSION / CRESCENDO PEDALS

EXPRESSION SHOE CAGE

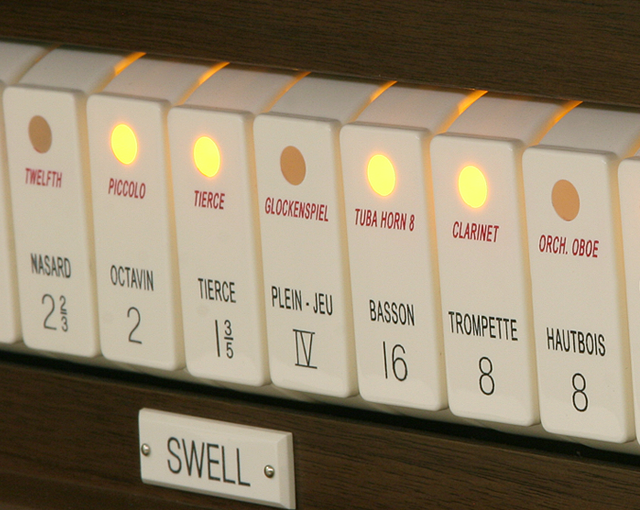

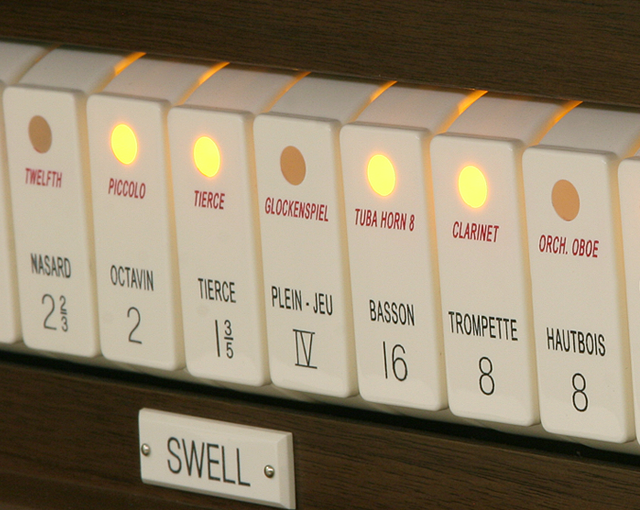

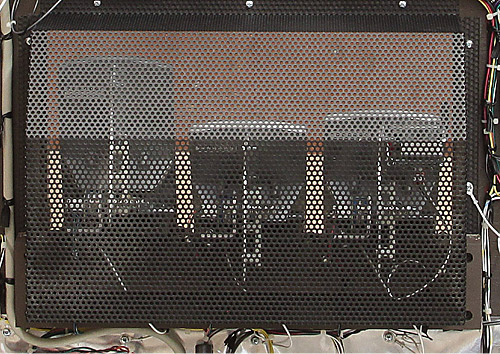

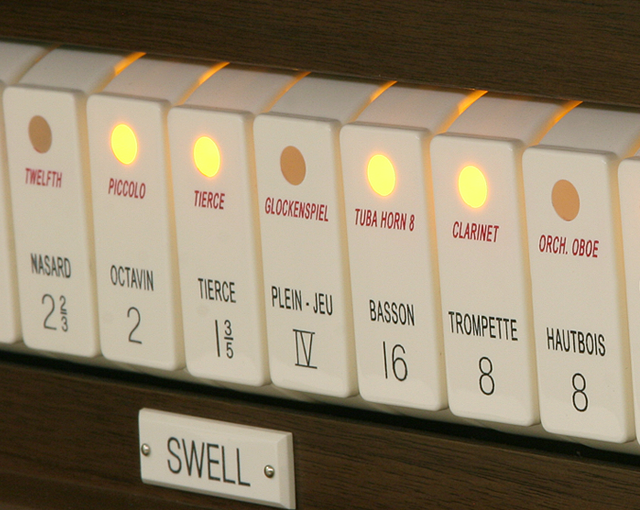

Allen designs and builds its own Theatre organ stop controls to provide the highest quality at affordable prices. From state-of-the-art Lumitech™ Stop Tabs with advanced LED's, to moving Stop Tabs, every control choice reflects Allen's uncompromising standards that ensure years of maintenance-free service.

HO-85 STOP LIST

PEDAL

32 PRINCIPAL BASSE

32 SOUBASSE

16 CONTRE BASSE

16 PRINCIPAL

16 SOUBASSE

16 BOURDON DOUX

16 VIOLON

8 OCTAVE

8 BOURDON

8 VIOLONCELLE

4 PRESTANT

4 FLÛTE

FOURNITURE IV

32 CONTRE BOMBARDE

16 BOMBARDE

16 POSAUNE

16 BASSON

8 TROMPETTE DE FÉTE (NC)

8 TROMPETTE

4 CLARION

GENISYS VOICE 1

GENISYS VOICE 2

SWELL

16 BOURDON DOUX

8 DIAPASON

8 COR DE NUIT

8 VIOLE DE GAMBA

8 VOIX CELESTE

4 OCTAVE

4 FLUTE TRAVERSIÈRE

2-2/3 NASARD

2 FLAGEOLET

1-3/5 TIERCE

PLEIN JEU IV

16 BOMBARDE

8 TUBA ANGLAIS (NC)

8 TROMPETTE DE FÉTE (NC)

8 TROMPETTE

8 HAUTBOIS

8 CLARINETTE

8 VOX HUMAINE

4 CLAIRON

CHIMES

TREMULANT

16 SWELL

UNISON OFF

4 SWELL

GENISYS VOICE 3

GENISYS VOICE 4

GREAT

16 PRINCIPAL

8 DIAPASON

8 MONTRE

8 FLÛTE HARMONIQUE

8 BOURDON

8 VIOLE

4 OCTAVE

4 FLÛTE CONIQUE

2-2/3 QUINTE

2 DOUBLETTE

FOURNITURE IV

CORNET V

CYMBALE IV

16 POSAUNE

8 TROMPETE

4 KLARIN

TREMULANT

GENISYS VOICE 5

GENISYS VOICE 6

CHOIR

16 QUINTATON

16 DULCIANA

8 PRINCIPAL

8 FLÛTE CREUSE

8 GEDACKT

8 DULCIANA

8 UNDA MARIS

4 PRESTANT

4 FLUTE DOUCE

4 DOLCAN CELESTE II

2 OCTAVIN

1-1/3 LARIGOT

PLEIN JEU VI

CORNET II

16 BASSON

8 TUBA ANGLAIS (NC)

8 PETITE TROMPETTE

8 CROMORNE

TREMULANT

GENISYS VOICE 7

GENISYS VOICE 8

SOLO

16 CELLOS CELESTE II

8 MAJOR DIAPASON

8 GROSSE FLÛTE

8 GAMBAS CELESTE II

8 FLÛTE CELESTE II

4 VIOLIN CELESTE II

DULCIANA MIXTURE V

16 CORNO DI BASSETTO

8 FRENCH HORN

8 COR ANGLAIS

8 VOX HUMANA

TREMULANT

GENISYS VOICE 9 (FOUR-MANUAL)

GENISYS VOICE 10 (FOUR-MANUAL)

COUPLERS

8 GREAT TO PEDAL

8 CHOIR TO PEDAL

8 SWELL TO PEDAL

4 SWELL TO PEDAL

16 SWELL TO GREAT

8 SWELL TO GREAT

4 SWELL TO GREAT

8 CHOIR TO GREAT

16 SWELL TO CHOIR

8 SWELL TO CHOIR

4 SWELL TO CHOIR

SOLO ON PEDAL

SOLO ON SWELL

SOLO ON GREAT

SOLO ON CHOIR

GENISYS VOICES COUPLE

CELESTES OFF

ALTERNATE TUNING

CG-CH TRANSFER

MELODY COUPLER SW>GT

BASS COUPLER

ANTIPHONAL ON

MAIN OFF

SOLO EXPRESS W/CH

SOLO UNENCLOSED

GT-PD UNENCLOSED

CHOIR UNISON OFF

CHOIR UNENCLOSED

TOE STUD

ZIMBELSTERN

TROMPETTE DE FÉTE

MIDI

MIDI ON PEDAL

MIDI ON SWELL

MIDI ON GREAT

MIDI ON CHOIR

Since entering the Buenos Aires Conservatory as a child prodigy at age six, Maestro Hector Olivera has become one of the most sought after and revered international concert organists of the present time.

'The Times Reporter', describes an evening with Mr. Olivera as: "An event, a happening, a joyful celebration of the sheer power and pressure that a true virtuoso like Hector Olivera can unleash in a concert hall."

Born in Buenos Aires, Mr. Olivera began playing the pipe organ when he was three. At age five he played for the legendary Eva Perón; at twelve he entered the University of Buenos Aires and by eighteen had performed for heads of state and celebrities throughout Latin America. When offered a scholarship at the renowned Juilliard School of Music in New York, he moved to the United States. Three years later, Mr. Olivera's outstanding professional concert career was launched when he won the AGO's National Improvisation Contest.

Mr. Olivera has performed solo concerts throughout the USA, Canada, Europe, Asia, Australia, Central and Latin America and as guest soloist with prominent symphony orchestras worldwide.

Whether in a prestigious venue like Carnegie Hall, Royal Albert Hall, Cathedral of Notre Dame in Paris, Constitution Hall, Walt Disney Concert Hall in Los Angeles, or in conjunction with a celebrated event like the Olympic games or the Classical Newport Music Festival, the most sophisticated and demanding organ aficionados claim that Maestro Hector Olivera is 'one of the greatest organists in the world today.'

< Harry Helmut, Hector's confidant, travels with Hector around the world to all his concerts. Harry gives Hector advice about performing and tours each performance location looking for good places to eat.

Rudolph A. Lucente has been associated with Allen Organs for over twenty years, and recently is known as the designer of the RL-66 and RL-90 organs, comprehensive three-manual and four-manual instruments that have met with acclaim from organists nationwide. He is an assistant organist at the Wanamaker Grand Court Organ in Philadelphia, and appears regularly at Longwood Gardens in Kennett Square, PA, The Kimmel Center for the Performing Arts in Philadelphia, and Boardwalk Hall in Atlantic City, New Jersey. As a recitalist, Rudy is known for his "family friendly" presentations and dedication programs. As a clinician, his fifty-plus years as a church musician have enabled him to assist workshop attendees in most aspects of their important ministry.

Rudy studied organ with Dr. Keith Chapman and also worked with the American/Armenian composer Richard Yardumian. Since their untimely deaths, Rudy has devoted much of his musical activities to the preservation and performance of their works.

Mr. Lucente appears frequently as a recitalist and church music clinician, and is a member of the Philadelphia Organ Quartet, an ensemble that performs music arranged for four organs.

The 66-Stop Rudy Lucente RL-66 Designer church organ is the culmination of his many years of experience in the Catholic music tradition. Employing Allen's advanced technology, the organ is designed with the versatility for both worship and concert use. The stop list includes principal choruses on all divisions and independent Festival Trumpet. The Allen RL-66 offers the flexibility of six specifications to compliment any style of music.

"The RL-90 meets the need for a larger instrument, allowing Allen to offer the right choice to customers seeking the particular capabilities of the RL organs. I incorporated many of the specification attributes from the fine pipe organs that I am privileged to play, and the samples in the RL-90 have been meticulously selected to provide a cohesive ensemble, rich texture, and extraordinary solo voices. It is a privilege to have been asked to assist in this design, and I am confident that the RL-90 will meet with the same success as has the RL-66."

"The process of creating these organs was an exciting and rewarding experience. The combination of Allen's superior technology and their flexibility has resulted in two truly comprehensive instruments." - Rudy Lucente

RL-66a STOP LIST

Standard stop lists: Classic Allen, English, Cavaillé-Coll, Schlicker, Arp Schnitger, Aeolian-Skinner

PEDAL

32 CONTRA VIOLONE

16 DIAPASON

16 BOURDON

16 BOURDON DOUX (SW)

16 VIOLONE (GT)

8 OCTAVE

8 GEDACKT FLÖTE

4 CHORAL BASS

4 FLUTE

MIXTURE IV

32 CONTRE BOMBARDE

16 BOMBARDE

16 CONTRE TROMPETTE (SW)

8 TRUMPET

4 CLARION

GENISYS VOICE 1

GENISYS VOICE 2

SWELL

8 GEIGEN DIAPASON

8 ROHR BOURDON

8 VIOLA POMPOSA

8 VIOLA CELESTE

8 FLUTE CELESTE II

4 OCTAVE GEIGEN

4 TRAVERSE FLUTE

2-2/3 NASARD [4 ORCH. FLUTE]

2 PICCOLO [8 CLARINET]

1-3/5 TIERCE [8 FRENCH HORN]

FOURNITURE IV

16 CONTRE TROMPETTE

8 TROMPETTE

8 OBOE

8 VOX HUMANA [COR ANGLAIS]

4 CLAIRON

TREMULANT

SWELL SOLO VOICES ON

16 SWELL

UNISON OFF

4 SWELL

CELESTA

GENISYS VOICE 3

GENISYS VOICE 4

GREAT

16 VIOLONE

8 DIAPASON

8 HARMONIC FLUTE

8 BOURDON

8 GAMBA

4 OCTAVE

4 FLUTE

2-2/3 TWELFTH

2 FIFTEENTH

MIXTURE IV

16 DOUBLE TRUMPET

8 TROMBA

TREMULANT

CHIMES

MELODY COUPLER CH>GT

GT-PD UNENCLOSED

BASS COUPLER

GT-CH MANUAL TRANSFER

GENISYS VOICE 5

GENISYS VOICE 6

CHOIR

16 ERZÄHLER

8 ENGLISH DIAPASON

8 HOLZ GEDACKT

8 ERZÄHLER

8 ERZÄHLER CELESTE

4 PRINZIPAL

4 KOPPELFLÖTE

4 ERZÄHLER CELESTE II

2 OKTAV

1-1/3 QUINTFLÖTE

ZIMBEL III

8 FESTIVAL TRUMPET

8 KRUMMHORN

TREMULANT

UNISON OFF

CHOIR UNENCLOSED

GENISYS VOICE 7

GENISYS VOICE 8

COUPLERS

8 GREAT TO PEDAL

8 SWELL TO PEDAL

4 SWELL TO PEDAL

8 CHOIR TO PEDAL

16 SWELL TO GREAT

8 SWELL TO GREAT

4 SWELL TO GREAT

8 CHOIR TO GREAT

16 SWELL TO CHOIR

8 SWELL TO CHOIR

4 SWELL TO CHOIR

GENISYS VOICES COUPLE

GENERAL

ALTERNATE TUNING

TREMULANTS FULL

ANTIPHONAL

SWELL MAINS OFF

SWELL TO ANTIPHONAL

GT-CH-PD MAINS OFF

GT-CH-PD TO ANTIPHONAL

TOE STUD

ZIMBELSTERN

MIDI

MIDI ON PEDAL

MIDI ON SWELL

MIDI ON GREAT

MIDI ON CHOIR

RL-90 STOP LIST

PEDAL

32 OPEN DIAPASON

32 CONTRE BOURDON

32 CONTRA VIOLONE

16 DIAPASON

16 SECOND DIAPASON (GT)

16 BOURDON

16 BOURDON DOUX (SW)

16 VIOLONE

16 CONTRA GAMBA (SO)

8 OCTAVE

8 GEDACKT FÖTE

8 GAMBA (SO)

4 CHORALBASS

4 FLUTE

MIXTURE IV

32 CONTRE BOMBARDE

32 CONTRA DOUBLE TRUMPET (GT)

16 BOMBARDE

16 DOUBLE TRUMPET (GT)

8 TROMPETTE

4 CLARION

GENISYS VOICE 1

GENISYS VOICE 2

SWELL

16 BOURDON DOUX

8 GEIGEN DIAPASON

8 GEDECKT

8 FLUTE CELESTE II

8 SALICIONAL

8 VOIX CELESTE

4 OCTAVE GEIGEN

4 TRAVERSE FLUTE

2-2/3 NASARD

2 FLAUTINO

1-3/5 TIERCE

FOURNITURE IV

16 POSAUNE

8 CORNOPEAN

8 OBOE D'AMOUR

8 VOX HUMANA

4 CLARION

TREMULANT

16 SWELL

UNISON OFF

4 SWELL

CELESTA

GENISYS VOICE 3

GENISYS VOICE 4

GREAT

16 DOUBLE DIAPASON

16 BOURDON

8 FIRST DIAPASON

8 SECOND DIAPASON

8 STOPPED DIAPASON

8 HARMONIC FLUTE

8 GAMBA

4 OCTAVE

4 SPITZ FLUTE

2-2/3 TWELFTH

2 FIFTEENTH

2 WALD FLUTE

MIXTURE IV

16 DOUBLE TRUMPET

8 TROMBA

TREMULANT

4 GREAT

CHIMES

GENISYS VOICE 5

GENISYS VOICE 6

CHOIR

16 CONTRA VIOLE

8 ENGLISH DIAPASON

8 CONCERT FLUTE

8 VIOLE

8 VIOLE CELESTE

4 OCTAVE

4 CHIMNEY FLUTE

4 VIOLES II

2 PICCOLO

1-1/3 QUINTFLÖTE

DULCIANA MIXTURE V

8 CLARINET

TREMULANT

UNISON OFF

GENISYS VOICE 7

GENISYS VOICE 8

SOLO

16 GAMBA

8 PRINCIPAL

8 FLAUTO MIRABILIS

8 SOLO GAMBA

8 GAMBA CELESTE

4 OCTAVE

4 GAMBETTE CELESTE II

GRAND MIXTURE V

16 TUBA MIRABILIS

8 TUBA MIRABILIS

8 FRENCH HORN

8 CORNO DI BASSETTO

8 ENGLISH HORN

4 OCTAVE MIRABILIS

TREMULANT

GENISYS VOICE 9

GENISYS VOICE 10

ANTIPHONAL

GT-PD MAINS OFF

GT-PD TO ANTIPHONAL

CHOIR MAINS OFF

CHOIR TO ANTIPHONAL

SWELL MAINS OFF

SWELL TO ANTIPHONAL

SOLO MAINS OFF

SOLO TO ANTIPHONAL

GENERAL

ALTERNATE TUNING

TREMULANTS FULL

SOLO UNENCLOSED

COUPLERS

8 GREAT TO PEDAL

4 GREAT TO PEDAL

8 SWELL TO PEDAL

4 SWELL TO PEDAL

8 CHOIR TO PEDAL

4 CHOIR TO PEDAL

8 SOLO TO PEDAL

4 SOLO TO PEDAL

16 SWELL TO GREAT

8 SWELL TO GREAT

4 SWELL TO GREAT

8 CHOIR TO GREAT

8 SOLO TO GREAT

16 SWELL TO CHOIR

8 SWELL TO CHOIR

4 SWELL TO CHOIR

8 SOLO TO CHOIR

8 SOLO TO SWELL

MELODY COUPLER CH>GT

GT-PD UNENCLOSED

BASS COUPLER

GT-CH MANUAL TRANSFER

GENISYS VOICE COUPLE

TOE STUD

ZIMBELSTERN

MIDI

MIDI ON PEDAL

MIDI ON SWELL

MIDI ON GREAT

MIDI ON CHOIR

MIDI ON SOLO

Concert and recording artist, composer, conductor and international television personality, Diane Bish has displayed her dazzling virtuosity and unique showmanship the world over. Her performances have been hailed by critics as "stunning, virtuoso, fiery, and astonishing". Through numerous recordings, concerts and weekly television appearances, Diane Bish is the most visible American organist today.

Diane is perhaps best known through the international television series, The Joy of Music, in which she combines exhilarating organ and ensemble performances with an informative, inspirational narrative and exciting world travel. In 25 years, over 500 programs have been recorded in famous cathedrals and concert halls on the organs of the world!

In 1989, Diane was awarded the National Citation by the National Federation of Music Clubs of America "for distinguished service to the musical, artistic, and cultural life of the nation," considered to be the Federation's highest honor. Diane Bish shares this rare distinction with such legends as Leonard Bernstein, Eugene Ormandy, Van Cliburn, Robert Shaw, Irving Berlin and Fred Waring.

DB-372 STOP LIST

PEDAL

32 CONTRA VIOLONE

16 DIAPASON

16 BOURDON

16 BOURDON DOUX (SW)

16 VIOLONE (GT)

8 OCTAVE

8 GEDACKT FLÖTE

4 CHORALBASS

4 FLUTE

MIXTURE IV

32 CONTRE BOMBARDE

16 BOMBARDE

16 CONTRE TROMPETTE (SW)

8 TRUMPET

4 CLARION

GENISYS VOICE 1

GENISYS VOICE 2

SWELL

16 BOURDON DOUX

8 ROHR BOURDON

8 FLUTE CELESTE II

8 VIOLA POMPOSA

8 VIOLA CELESTE

4 OCTAVE GEIGEN

4 TRAVERSE FLUTE

2-2/3 NASARD [8 ORCH. FLUTE]

2 PICCOLO [8 CLARINET]

1-3/5 TIERCE [8 FRENCH HORN]

FOURNITURE IV

16 CONTRE TROMPETTE

8 TROMPETTE

8 OBOE

8 VOX HUMANA [COR ANGLAIS]

4 CLAIRON

CELESTA

16 SWELL

UNISON OFF

4 SWELL

TREMULANT

SWELL SOLO VOICES ON

GENISYS VOICE 3

GENISYS VOICE 4

GREAT

16 VIOLONE

8 DIAPASON

8 HARMONIC FLUTE

8 BOURDON

8 GAMBA

4 OCTAVE

4 FLUTE

2-2/3 TWELFTH

2 FIFTEENTH

MIXTURE IV

CYMBALE III

8 TROMBA

TREMULANT

CHIMES

GENISYS VOICE 5

GENISYS VOICE 6

GT-PD UNENCLOSED

BASS COUPLER

MELODY COUPLER CH>GT

BASS COUPLER

CHOIR

16 ERZÄHLER

8 HOLZ GEDACKT

8 ERZÄHLER

8 ERZÄHLER CELESTE

4 PRINZIPAL

4 KOPPELFLÖTE

4 ERZÄHLER CELESTE II

2 OKTAV

1 1/3 QUINTFLÖTE

ZIMBEL III

16 RANKETT

8 FESTIVAL TRUMPET

8 KRUMMHORN

CHOIR UNISON OFF

TREMULANT

CHOIR UNENCLOSED

GENISYS VOICE 7

GENISYS VOICE 8

GENERAL

GT-CH MANUAL TRANSFER

ALTERNATE TUNING

TREMULANTS FULL

COUPLERS

8 GREAT TO PEDAL

8 SWELL TO PEDAL

4 SWELL TO PEDAL

8 CHOIR TO PEDAL

16 SWELL TO GREAT

8 SWELL TO GREAT

4 SWELL TO GREAT

8 CHOIR TO GREAT

16 SWELL TO CHOIR

8 SWELL TO CHOIR

4 SWELL TO CHOIR

GENISYS VOICE COUPLE

ANTIPHONAL

SWELL MAINS OFF

SWELL TO ANTIPHONAL

GT-CH-PD MAINS OFF

GT-CH-PD TO ANTIPHONAL

MIDI

MIDI ON PEDAL

MIDI ON SWELL

MIDI ON GREAT

MIDI ON CHOIR

PISTON

ZIMBELSTERN

ITALICS INDICATE SWELL SOLO VOICES

Aram Basmadjian is one of the most accomplished organ virtuosos in America. He provides diverse programs that have won acclaim from audiences and critics alike for being musically appropriate for all audiences. Aram has several recordings on Allen instruments, and continues his career as a touring concert artist, having spent six years with Community Concerts with performances in over 50 cities throughout the United States each year. These programs utilized Aram's own Allen four-manual touring organ. Aram currently serves as the Organist/Choirmaster at Trinity Episcopal Church in Bethlehem, PA, and is also Executive Vice President of Sales of Allen Organ Company.

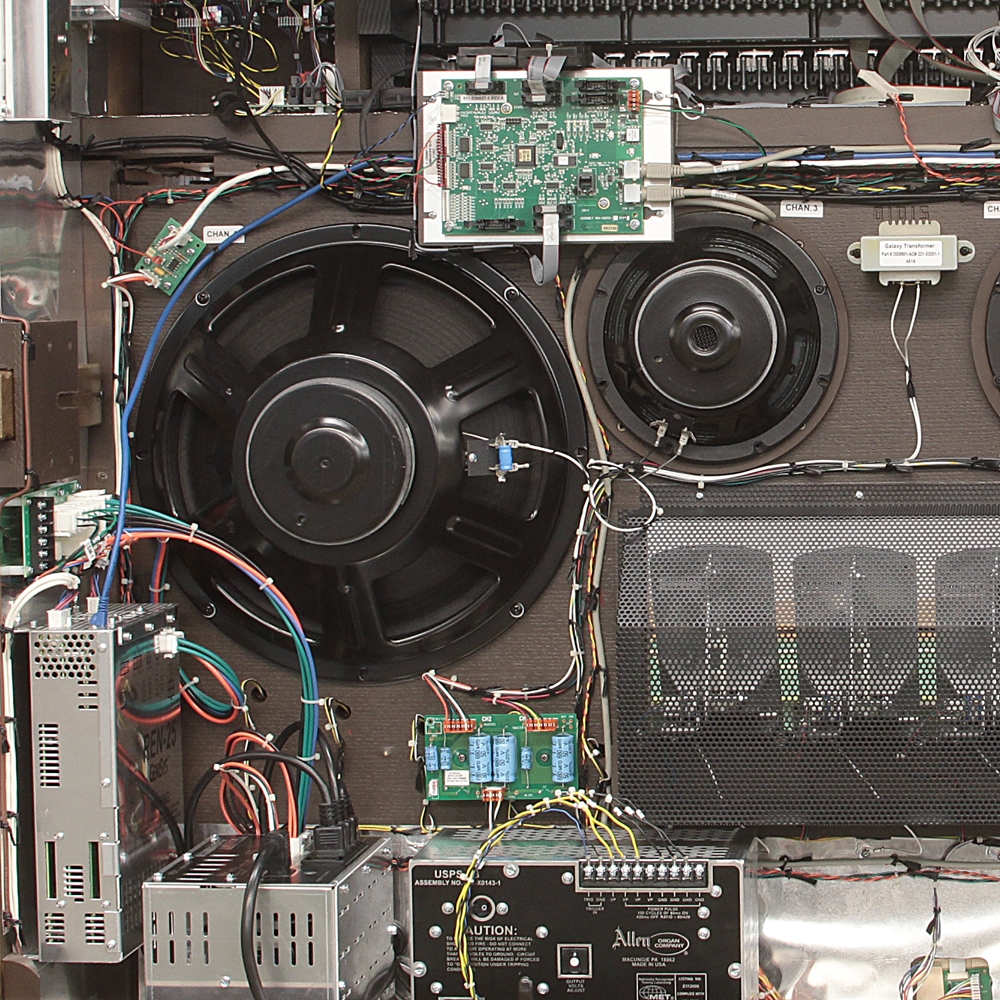

About the ABIII/68

This 68-stop Aram Basmadjian design can effectively and convincingly play music of all styles and eras with equal facility. Employing Allen's state-of-the-art GENISYS™ Technology, the organ is equally at home in a church sanctuary or the concert hall.

"The design emphasizes the apotheosis of American organ building as conceived by legendary organ designer, G. Donald Harrison, during the mid-twentieth century. Rich foundation tones with brilliant mixtures, colorful flutes, imitative solo reeds and warm string-toned stops indulge the organist with great musical versatility.

The organ incorporates a 34-channel audio system. The unique audio design employs specialized speaker cabinets for upper-range voices allowing this expansive audio system to produce sound with impressive clarity and spaciousness, yet fit comfortably into chambers of moderate size."

- Aram Basmadjian

ABIII/68 STOP LIST

PEDAL

32 CONTRA BOURDON

16 DIAPASON

16 BOURDON

16 BOURDON DOUX (SW)

16 VIOLONE (GT)

16 DULCIANA (CH)

8 OCTAVE

8 GEDECKT

4 GEDECKT

MIXTURE IV

32 CONTRE BOMBARDE

16 BOMBARDE

16 WALDHORN (SW)

8 TRUMPET

4 CLARION

GENISYS VOICE 1

GENISYS VOICE 2

SWELL

8 DIAPASON

8 ROHR FLUTE

8 FLUTE CELESTE II

8 SALICIONAL

8 VOIX CELESTE

4 OCTAVE GEIGEN

4 TRIANGLE FLUTE

2-2/3 NASARD [8 FLAUTO MIRABILIS]

2 OCTAVIN [8 CLARINET]

1-3/5 TIERCE [8 FRENCH HORN]

MIXTURE V

16 WALDHORN

8 TROMPETTE

8 OBOE

8 VOX HUMANA [COR ANGLAIS]

4 CLAIRON

CELESTA

16 SWELL

UNISON OFF

4 SWELL

TREMULANT

SWELL SOLO VOICES ON

GENISYS VOICE 3

GENISYS VOICE 4

GREAT

16 VIOLONE

8 FIRST DIAPASON

8 SECOND DIAPASON

8 BOURDON

8 GAMBA

4 OCTAVE

4 FLUTE

2-2/3 TWELFTH

2 FIFTEENTH

MIXTURE IV

8 TROMBA

4 CLARION

CHIMES

TREMULANT

GENISYS VOICE 5

GENISYS VOICE 6

GT-PD EXPRESS W/CHOIR

BASS COUPLER

MELODY COUPLER CH>GT

GT-CH MANUAL TRANSFER

CHOIR

16 DULCIANA

8 GEIGEN PRINCIPAL

8 CONCERT FLUTE

8 ERZÄHLER

8 ERZÄHLER CELESTE

8 DULCIANA

8 UNDA MARIS

4 PRINZIPAL

4 FLÚTE D’ AMORE

4 DULCIANA

2 PICCOLO

CARILLON III

8 TUBA MIRABILIS

8 CROMORNE

TREMULANT

GENISYS VOICE 7

GENISYS VOICE 8

UNISON OFF

CHOIR UNENCLOSED

COUPLERS

8 GREAT TO PEDAL

8 SWELL TO PEDAL

4 SWELL TO PEDAL

8 CHOIR TO PEDAL

16 SWELL TO GREAT

8 SWELL TO GREAT

4 SWELL TO GREAT

8 CHOIR TO GREAT

16 SWELL TO CHOIR

8 SWELL TO CHOIR

4 SWELL TO CHOIR

GENISYS VOICE COUPLE

GENERAL

ALTERNATE TUNING

TREMULANTS FULL

REEDS OFF

MIXTURES OFF

PEDAL DIVIDE

TOE STUD

ZIMBELSTERN

MIDI

MIDI ON PEDAL

MIDI ON SWELL

MIDI ON GREAT

MIDI ON CHOIR

ITALICS INDICATE SWELL SOLO VOICES

GX-570a STOP LIST

Standard stop lists: Classic Allen, English, Cavaillé-Coll, Schlicker, Arp Schnitger, Aeolian-Skinner

PEDAL

64 RESULTANT

32 CONTRE BOURDON

32 CONTRA VIOLONE

32 GAMBA (ST)

32 VIOLONE (ST)

16 DIAPASON

16 BOURDON

16 BOURDON DOUX (SW)

16 VIOLONE

16 GAMBA (ST)

16 VIOLONE (ST)

8 OCTAVE

8 GEDACKT FLÖTE

4 CHORALBASS

4 FLÛTE

MIXTURE IV

32 CONTRE BOMBARDE

32 CONTRA DOUBLE TRUMPET (GT)

16 BOMBARDE

16 DOUBLE TRUMPET (GT)

8 TROMPETTE

4 CLARION

GENISYS VOICE 1

GENISYS VOICE 2

SWELL

16 BOURDON DOUX

8 GEIGEN DIAPASON

8 BOURDON

8 FLUTE CELESTE II

8 SALICIONAL

8 VOIX CELESTE

4 OCTAVE GEIGEN

4 TRAVERSE FLUTE

2 2/3 NASARD

2 PICCOLO

1 3/5 TIERCE

FOURNITURE IV

16 CONTRE TROMPETTE

8 TROMPETTE

8 HAUTBOIS

8 VOX HUMANA

4 CLAIRON

CELESTA (SO)

TREMULANT

16 SWELL

UNISON OFF

4 SWELL

GENISYS VOICE 3

GENISYS VOICE 4

STRING

1ST VIOLE II

2ND VIOLE II

8 GAMBA II

8 SALICIONAL II

4 DULCET II

4 SALICET II

2 VIOLINA II

DULCIANA MIXTURE V

TREMULANT

CELESTES OFF

16 PEDAL STRINGS

8 PEDAL STRINGS

4 PEDAL STRINGS

STRING EXPRESS W/SWELL

STRING EXPRESS W/GREAT-PEDAL

STRING EXPRESS W/CHOIR

GENISYS VOICE 11

GENISYS VOICE 12

GREAT

16 DOUBLE DIAPASON

16 BOURDON

8 DIAPASON

8 HARMONIC FLUTE

8 BOURDON

8 GAMBA

4 OCTAVE

4 SPITZ FLUTE

2 2/3 TWELFTH

2 FIFTEENTH

2 WALD FLUTE

MIXTURE IV

SHARP MIXTURE III

16 DOUBLE TRUMPET

8 TROMBA

CHIMES

TREMULANT

GT-PD UNENCLOSED

BASS COUPLER

GENISYS VOICE 5

GENISYS VOICE 6

CHOIR

16 CONTRA VIOLE

8 DIAPASON

8 HOLZ GEDACKT

8 VIOLE

8 VIOLE CELESTE

4 PRINZIPAL

4 KOPPELFLÖTE

4 VIOLES II

2 OKTAV

1 1/3 QUINTFLÖTE

CYMBALE III

8 CROMORNE

TREMULANT

GENISYS VOICE 7

GENISYS VOICE 8

CHOIR UNISON OFF

CHOIR UNENCLOSED

MELODY COUPLER CH>GT

GT-CH MANUAL TRANSFER

CHOIR MAINS OFF

CHOIR TO ANTIPHONAL

SOLO

16 GAMBA CELESTE II

8 FLAUTO MIRABILIS

8 SOLO GAMBA

8 GAMBA CELESTE

4 GAMBETTE CELESTE II

16 TUBA MIRABILIS

8 FESTIVAL TRUMPET

8 TUBA MIRABILIS

8 FRENCH HORN

8 CORNO DI BASSETTO

8 COR ANGLAIS

4 OCTAVE MIRABILIS

CELESTA

HARPSICHORD

TREMULANT

GENISYS VOICE 9

GENISYS VOICE 10

COUPLERS

8 GREAT TO PEDAL

4 GREAT TO PEDAL

8 SWELL TO PEDAL

4 SWELL TO PEDAL

8 CHOIR TO PEDAL

8 SOLO TO PEDAL

8 SOLO TO SWELL

16 SWELL TO GREAT

8 SWELL TO GREAT

4 SWELL TO GREAT

8 CHOIR TO GREAT

8 SOLO TO GREAT

16 SWELL TO CHOIR

8 SWELL TO CHOIR

4 SWELL TO CHOIR

8 SOLO TO CHOIR

16 STRING ON SWELL

8 STRING ON SWELL

4 STRING ON SWELL

16 STRING ON GREAT

8 STRING ON GREAT

4 STRING ON GREAT

16 STRING ON CHOIR

8 STRING ON CHOIR

4 STRING ON CHOIR

16 STRING ON SOLO

8 STRING ON SOLO

4 STRING ON SOLO

GENISYS VOICES COUPLE

GENERAL

ALL SWELLS TO SWELL

SOLO UNENCLOSED

TREMULANTS FULL

ALTERNATE TUNING

ANTIPHONAL

GT-PD MAINS OFF

GT-PD TO ANTIPHONAL

SOLO MAINS OFF

SOLO TO ANTIPHONAL

SWELL MAINS OFF

SWELL TO ANTIPHONAL

STRING MAINS OFF

STRING TO ANTIPHONAL

MIDI

MIDI ON PEDAL

MIDI ON SWELL

MIDI ON STRING

MIDI ON GREAT

MIDI ON CHOIR

MIDI ON SOLO

TOE STUD

ZIMBELSTERN

From the multiple stop list versatility to the distinct sounds available in all ALLEN organs, each stop list is independently voiced with its own audio settings.

CLASSIC ALLEN

The "signature" specification that made Allen the world's favorite organ! Allen tonal directors created the specifications of Allen digital organs by selecting their favorite samples from fine pipe organs throughout the world.

ENGLISH (mainly Willis samples)

Characterized by Diapasons and weighty reeds, this style of organ building was brought to its height by renowned 19th-century British organ craftsman Henry Willis.

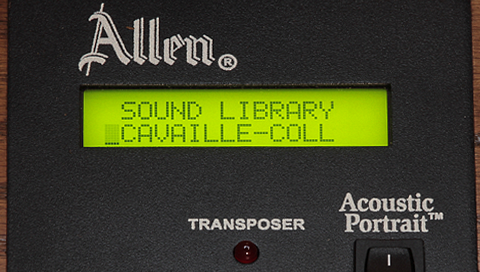

CAVAILLÉ-COLL/French Romantic

Progenitor and master of the 19th-century French style with fiery and dominant reeds; symphonic tonal schemes.

SCHLICKER/Neo-Baroque

Neo-Baroque scalings by The Schlicker Organ Company; 20th-century revival of 17th-century North German ideals.

ARP SCHNITGER

Master German builder who brought the bright, incisive Werkprinzip style to its zenith.

AEOLIAN-SKINNER

Under the tonal direction of G. Donald Harrison, this company developed the American Classic tonal design, characterized by firm and articulate principals, bright mixtures and French-style reeds. Its versatility enables the American Classic to authentically perform a broad range of musical styles.

ALLEN EXPRESSION / CRESCENDO PEDALS

EXPRESSION SHOE CAGE

GX-470a STOP LIST

Standard stop lists: Classic Allen, English, Cavaillé-Coll, Schlicker, Arp Schnitger, Aeolian-Skinner

PEDAL

64 RESULTANT

32 CONTRE BOURDON

32 CONTRA VIOLONE

32 GAMBA (ST)

32 VIOLONE (ST)

16 DIAPASON

16 BOURDON

16 BOURDON DOUX (SW)

16 VIOLONE

16 GAMBA (ST)

16 VIOLONE (ST)

8 OCTAVE

8 GEDACKT FLÖTE

4 CHORALBASS

4 FLÛTE

MIXTURE IV

32 CONTRE BOMBARDE

32 CONTRA DOUBLE TRUMPET (GT)

16 BOMBARDE

16 DOUBLE TRUMPET (GT)

8 TROMPETTE

4 CLARION

GENISYS VOICE 1

GENISYS VOICE 2

SWELL

16 BOURDON DOUX

8 GEIGEN DIAPASON

8 BOURDON

8 FLUTE CELESTE II

8 SALICIONAL

8 VOIX CELESTE

4 OCTAVE GEIGEN

4 TRAVERSE FLUTE

2 2/3 NASARD

2 PICCOLO

1 3/5 TIERCE

FOURNITURE IV

16 CONTRE TROMPETTE

8 TROMPETTE

8 HAUTBOIS

8 VOX HUMANA

4 CLAIRON

CELESTA (SO)

TREMULANT

16 SWELL

UNISON OFF

4 SWELL

GENISYS VOICE 3

GENISYS VOICE 4

STRING

1ST VIOLE II

2ND VIOLE II

8 GAMBA II

8 SALICIONAL II

4 DULCET II

4 SALICET II

2 VIOLINA II

DULCIANA MIXTURE V

TREMULANT

CELESTES OFF

16 PEDAL STRINGS

8 PEDAL STRINGS

4 PEDAL STRINGS

STRING EXPRESS W/SWELL

STRING EXPRESS W/GREAT-PEDAL

STRING EXPRESS W/CHOIR

GREAT

16 DOUBLE DIAPASON

16 BOURDON

8 DIAPASON

8 HARMONIC FLUTE

8 BOURDON

8 GAMBA

4 OCTAVE

4 SPITZ FLUTE

2 2/3 TWELFTH

2 FIFTEENTH

2 WALD FLUTE

MIXTURE IV

SHARP MIXTURE III

16 DOUBLE TRUMPET

8 TROMBA

CHIMES

TREMULANT

GT-PD UNENCLOSED

BASS COUPLER

GENISYS VOICE 5

GENISYS VOICE 6

CHOIR

16 CONTRA VIOLE

8 DIAPASON

8 HOLZ GEDACKT

8 VIOLE

8 VIOLE CELESTE

4 PRINZIPAL

4 KOPPELFLÖTE

4 VIOLES II

2 OKTAV

1 1/3 QUINTFLÖTE

CYMBALE III

8 CROMORNE

TREMULANT

GENISYS VOICE 7

GENISYS VOICE 8

CHOIR UNISON OFF

CHOIR UNENCLOSED

MELODY COUPLER CH>GT

GT-CH MANUAL TRANSFER

CHOIR MAINS OFF

CHOIR TO ANTIPHONAL

SOLO

16 GAMBA CELESTE II

8 FLAUTO MIRABILIS

8 SOLO GAMBA

8 GAMBA CELESTE

4 GAMBETTE CELESTE II

16 TUBA MIRABILIS

8 FESTIVAL TRUMPET

8 TUBA MIRABILIS

8 FRENCH HORN

8 CORNO DI BASSETTO

8 COR ANGLAIS

4 OCTAVE MIRABILIS

CELESTA

HARPSICHORD

TREMULANT

GENISYS VOICE 9

GENISYS VOICE 10

COUPLERS

8 GREAT TO PEDAL

4 GREAT TO PEDAL

8 SWELL TO PEDAL

4 SWELL TO PEDAL

8 CHOIR TO PEDAL

8 SOLO TO PEDAL

8 SOLO TO SWELL

16 SWELL TO GREAT

8 SWELL TO GREAT

4 SWELL TO GREAT

8 CHOIR TO GREAT

8 SOLO TO GREAT

16 SWELL TO CHOIR

8 SWELL TO CHOIR

4 SWELL TO CHOIR

8 SOLO TO CHOIR

16 STRING ON SWELL

8 STRING ON SWELL

4 STRING ON SWELL

16 STRING ON GREAT

8 STRING ON GREAT

4 STRING ON GREAT

16 STRING ON CHOIR

8 STRING ON CHOIR

4 STRING ON CHOIR

16 STRING ON SOLO

8 STRING ON SOLO

4 STRING ON SOLO

GENISYS VOICES COUPLE

GENERAL

ALL SWELLS TO SWELL

SOLO UNENCLOSED

TREMULANTS FULL

ALTERNATE TUNING

ANTIPHONAL

GT-PD MAINS OFF

GT-PD TO ANTIPHONAL

SOLO MAINS OFF

SOLO TO ANTIPHONAL

SWELL MAINS OFF

SWELL TO ANTIPHONAL

STRING MAINS OFF

STRING TO ANTIPHONAL

MIDI

MIDI ON PEDAL

MIDI ON SWELL

MIDI ON GREAT

MIDI ON CHOIR

MIDI ON SOLO

TOE STUD

ZIMBELSTERN

From the multiple stop list versatility to the distinct sounds available in all ALLEN organs, each stop list is independently voiced with its own audio settings.

CLASSIC ALLEN

The "signature" specification that made Allen the world's favorite organ! Allen tonal directors created the specifications of Allen digital organs by selecting their favorite samples from fine pipe organs throughout the world.

ENGLISH (mainly Willis samples)

Characterized by Diapasons and weighty reeds, this style of organ building was brought to its height by renowned 19th-century British organ craftsman Henry Willis.

CAVAILLÉ-COLL/French Romantic

Progenitor and master of the 19th-century French style with fiery and dominant reeds; symphonic tonal schemes.

SCHLICKER/Neo-Baroque

Neo-Baroque scalings by The Schlicker Organ Company; 20th-century revival of 17th-century North German ideals.

ARP SCHNITGER

Master German builder who brought the bright, incisive Werkprinzip style to its zenith.

AEOLIAN-SKINNER

Under the tonal direction of G. Donald Harrison, this company developed the American Classic tonal design, characterized by firm and articulate principals, bright mixtures and French-style reeds. Its versatility enables the American Classic to authentically perform a broad range of musical styles.

ALLEN EXPRESSION / CRESCENDO PEDALS

EXPRESSION SHOE CAGE

GX-460a STOP LIST

Standard stop lists: Classic Allen, English, Cavaillé-Coll, Schlicker, Arp Schnitger, Aeolian-Skinner

PEDAL

64 RESULTANT

32 CONTRA VIOLONE

32 CONTRE BOURDON

16 DIAPASON

16 BOURDON

16 BOURDON DOUX (SW)

16 VIOLONE

16 CONTRA GAMBA (SO)

8 OCTAVE

8 GEDACKT FLÖTE

8 GAMBA (SO)

4 CHORALBASS

4 FLÛTE

MIXTURE IV

32 CONTRE BOMBARDE

32 CONTRA DOUBLE TRUMPET (GT)

16 BOMBARDE

16 DOUBLE TRUMPET (GT)

8 TROMPETTE

4 CLARION

GENISYS VOICE 1

GENISYS VOICE 2

SWELL

16 BOURDON DOUX

8 GEIGEN DIAPASON

8 BOURDON

8 FLUTE CELESTE II

8 SALICIONAL

8 VOIX CELESTE

4 OCTAVE GEIGEN

4 TRAVERSE FLUTE

2 2/3 NASARD

2 PICCOLO

1 3/5 TIERCE

FOURNITURE IV

16 CONTRE TROMPETTE

8 TROMPETTE

8 HAUTBOIS

8 VOX HUMANA

4 CLAIRON

CELESTA (SO)

HARPSICHORD (SO)

16 SWELL

UNISON OFF

4 SWELL

TREMULANT

ALL SWELLS TO SWELL

GENISYS VOICE 3

GENISYS VOICE 4

GREAT

16 DOUBLE DIAPASON

16 BOURDON

8 DIAPASON

8 HARMONIC FLUTE

8 BOURDON

8 GAMBA

4 OCTAVE

4 SPITZ FLUTE

2 2/3 TWELFTH

2 FIFTEENTH

2 WALD FLUTE

MIXTURE IV

SHARP MIXTURE III

16 DOUBLE TRUMPET

8 TROMBA

CHIMES

TREMULANT

GT-PD UNENCLOSED

GENISYS VOICE 5

GENISYS VOICE 6

CHOIR

16 CONTRA VIOLE

8 DIAPASON

8 HOLZ GEDACKT

8 VIOLE

8 VIOLE CELESTE

4 PRINZIPAL

4 KOPPELFLÖTE

4 VIOLES II

2 OKTAV

1 1/3 QUINTFLÖTE

CYMBALE III

8 CROMORNE

TREMULANT

GT-CH MANUAL TRANSFER

GENISYS VOICE 7

GENISYS VOICE 8

SOLO

16 GAMBA CELESTE II

8 SOLO GAMBA

8 GAMBA CELESTE

4 GAMBETTE CELESTE II

8 FLAUTO MIRABILIS

8 FRENCH HORN

8 CORNO DI BASSETTO

8 COR ANGLAIS

TREMULANT

16 TUBA MIRABILIS

8 TUBA MIRABILIS

4 OCTAVE MIRABILIS

CELESTA

SOLO UNENCLOSED

GENISYS VOICE 9

GENISYS VOICE 10

COUPLERS

8 GREAT TO PEDAL

4 GREAT TO PEDAL

8 SWELL TO PEDAL

4 SWELL TO PEDAL

8 CHOIR TO PEDAL

8 SOLO TO PEDAL

16 SWELL TO GREAT

8 SWELL TO GREAT

4 SWELL TO GREAT

8 CHOIR TO GREAT

8 SOLO TO GREAT

16 SWELL TO CHOIR

8 SWELL TO CHOIR

4 SWELL TO CHOIR

CHOIR UNISON OFF

8 SOLO TO CHOIR

8 SOLO TO SWELL

BASS COUPLER

MELODY COUPLER CH>GT

GT-CH MANUAL TRANSFER

GENISYS VOICES COUPLE

GENERAL

ALTERNATE TUNING

TREMULANTS FULL

ANTIPHONAL

GT-PD MAINS OFF

GT-PD TO ANTIPHONAL

CHOIR MAINS OFF

CHOIR TO ANTIPHONAL

SWELL MAINS OFF

SWELL TO ANTIPHONAL

SOLO MAINS OFF

SOLO TO ANTIPHONAL

MIDI

MIDI ON PEDAL

MIDI ON SWELL

MIDI ON GREAT

MIDI ON CHOIR

MIDI ON SOLO

From the multiple stop list versatility to the distinct sounds available in all ALLEN organs, each stop list is independently voiced with its own audio settings.

CLASSIC ALLEN

The "signature" specification that made Allen the world's favorite organ! Allen tonal directors created the specifications of Allen digital organs by selecting their favorite samples from fine pipe organs throughout the world.

ENGLISH (mainly Willis samples)

Characterized by Diapasons and weighty reeds, this style of organ building was brought to its height by renowned 19th-century British organ craftsman Henry Willis.

CAVAILLÉ-COLL/French Romantic

Progenitor and master of the 19th-century French style with fiery and dominant reeds; symphonic tonal schemes.

SCHLICKER/Neo-Baroque

Neo-Baroque scalings by The Schlicker Organ Company; 20th-century revival of 17th-century North German ideals.

ARP SCHNITGER

Master German builder who brought the bright, incisive Werkprinzip style to its zenith.

AEOLIAN-SKINNER

Under the tonal direction of G. Donald Harrison, this company developed the American Classic tonal design, characterized by firm and articulate principals, bright mixtures and French-style reeds. Its versatility enables the American Classic to authentically perform a broad range of musical styles.

Allen designs and builds its own controls to provide the highest quality at affordable prices. From state-of-the-art Lumitech™ stops with advanced LED's to moving drawknobs, every control choice reflects Allen's uncompromising standards that ensure years of maintenance-free service.

The HISTORIQUE IIIG, 34 Stop, Two-manual organ is equipped with Allen's efficient LED stop controls.

HISTORIQUE IIIG STOP LIST

Standard stop lists: Classic Allen, English, Cavaillé-Coll, Schlicker, Arp Schnitger, Aeolian-Skinner, Wurlitzer, Barton, Morton

PEDAL

16 BOURDON

16 BOURDON DOUX (SW)

8 OCTAVE

8 GEDACKTFLÖTE

4 CHORAL BASS

MIXTURE IV

16 POSAUNE

4 CLARION

GENISYS VOICE 1 (OPTIONAL)

GENISYS VOICE 2 (OPTIONAL)

GREAT TO PEDAL

SWELL TO PEDAL

POSITIV TO PEDAL

BASS COUPLER

SWELL

8 GEDACKT

8 SALICIONAL

8 VOIX CELESTE

4 PRINCIPAL

4 TRAVERS-FLÖTE

2-2/3 NASAT

2 BLOCKFLÖTE

1-3/5 TIERCE

MIXTURE IV

16 BASSON

8 TROMPETTE

GENISYS VOICE 3 (OPTIONAL)

GENISYS VOICE 4 (OPTIONAL)

TREMULANT

GREAT

16 LIEBLICH GEDACKT (SW)

8 PRINCIPAL

8 HARMONIC FLUTE

4 OCTAVE

4 SPITZFLÖTE

2 SUPER OCTAVE

MIXTURE IV

8 TROMPETTE

GENISYS VOICE 5 (OPTIONAL)

GENISYS VOICE 6 (OPTIONAL)

TREMULANT

SWELL TO GREAT

POSITIV TO GREAT

ALTERNATE TUNING

GT-PD UNENCLOSED

POSITIV

8 HOLZ GEDACKT

4 PRINZIPAL

4 KOPPELFLÖTE

2 OKTAVE

1 1/3 QUINTFLÖTE

MIXTURE II

8 KRUMMHORN

GENISYS VOICE 7 (OPTIONAL)

GENISYS VOICE 8 (OPTIONAL)

TREMULANT

SWELL TO POSITIV

GENISYS VOICES COUPLE

MIDI

MIDI ON PEDAL